NIOSH Proposes RELs for Diacetyl and 2,3-Pentanedione

The agency recommends a recommended exposure limit of 5 ppb for diacetyl as a time-weighted average for up to 8 hours/day during a 40-hour work week and a short-term exposure limit of 25 parts per billion for a 15-minute time period.

- By Jerry Laws

- Feb 01, 2017

NIOSH recently published recommended exposure limits for diacetyl and 2,3-pentanedione, which are widely used food flavoring compounds that have been linked to decreased lung function in exposed workers. The RELs were published Oct. 31, 2016, in a document titled Criteria for a Recommended Standard: Occupational Exposure to Diacetyl and 2,3-Pentanedione.

"Flavorings used in food products are often complex mixtures of natural and manmade compounds. While considered safe to eat, these compounds might still be harmful to breathe in the forms and amounts to which workers in the food and chemical industries may be exposed," according to the agency. "To protect workers, NIOSH recommends a REL of 5 ppb for diacetyl as a time-weighted average (TWA) for up to 8 hours/day during a 40-hour work week. To further protect against effects of short-term exposures, NIOSH recommends a short-term exposure limit for diacetyl of 25 parts per billion for a 15-minute time period. Additionally, NIOSH recommends keeping exposure to 2,3-pentanedione below 9.3 ppb as an 8-hour TWA during a 40-hour work week." The REL is slightly higher than the REL for diacetyl due to analytical method limitations, according to the agency, which also recommended a short-term exposure limit (STEL) for 2,3-pentanedione of 31 parts per billion during a 15-minute period based on a concern that peak exposures may have increased toxicity than the same total dose spread out for a longer period of time.

Although 2,3-pentanedione is used as a substitute for diacetyl, it, too, is of concern because of structural similarities to diacetyl and because animal studies have shown similar respiratory toxicity, the document's executive summary states.

"We know these flavoring compounds can pose a great risk for workers who may be exposed on the job, causing serious and irreversible damage to their lungs," said NIOSH Director Dr. John Howard, M.D., MPH. "This Criteria Document reflects not only our review of the science and understanding of the hazard, but also outlines our recommendations for controlling workplace exposures to these compounds. With the release of this document, NIOSH is taking an important step in protecting the health and safety of all those who may be exposed to these compounds while on the job."

The document summarizes current scientific knowledge and proposes measures such as engineering controls for curbing work-related exposures to both compounds, based on the current state of knowledge.

NIOSH already conducted numerous studies; reviewed the scientific literature on exposures, toxicology, and engineering controls; and subsequently conducted a quantitative risk assessment before issuing the document, which it said had undergone a rigorous scientific process including peer, stakeholder, and public review. NIOSH continues to collect information through its Health Hazard Evaluation program for companies where workers may be exposed to the compounds.

Researching Flavorings-Related Lung Disease

For more information and resources to reduce the risk of obliterative bronchiolitis associated with occupational exposures to flavorings, visit NIOSH's topic page1 on flavorings-related lung disease.

The agency's topic page cites the well-known August 2000 case in which the Missouri Department of Health and Senior Services requested technical assistance from NIOSH in an investigation of obliterative bronchiolitis, in former workers of a microwave popcorn plant in Jasper, Mo.

NIOSH eventually researched the case in collaboration with the microwave popcorn industry and flavorings manufacturers, using the findings in a 2004 NIOSH Alert titled "Preventing Lung Disease in Workers Who Use or Make Flavorings."

The executive summary2 notes that diacetyl and 2,3-pentanedione are found in cigarette smoke and in some flavored e-cigarettes. The document’s third chapter discusses increased prevalence of airway obstructions in smokers who are exposed to diacetyl versus smokers generally in the U.S. population. "Most importantly," it says, "because diacetyl causes obstructive lung disease and because smoking causes obstructive lung disease, the presence of diacetyl in cigarette smoke in no way diminishes the need to control diacetyl exposures in employees."

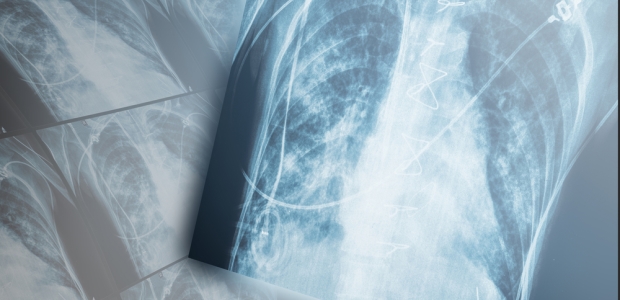

"Although much remains unknown regarding the toxicity of flavoring-related chemicals, employers and workers can take steps to address working conditions and work practices that place workers at risk," according to the agency. This obstructive lung disease can be severe: Lung biopsies revealed some workers in the industry suffer from constrictive bronchiolitis obliterans, which causes the smallest airways in the lung to become scarred and constricted, blocking the movement of air.

"The main respiratory symptoms experienced by workers affected by obliterative bronchiolitis include cough (usually without phlegm), wheezing, and worsening shortness of breath on exertion. The severity of the lung symptoms can range from only a mild cough to severe cough and shortness of breath on exertion. These symptoms typically do not improve when the worker goes home at the end of the workday or on weekends or vacations. Usually these symptoms are gradual in onset and progressive, but severe symptoms can occur suddenly. Some workers may experience fever, night sweats, and weight loss. Before arriving at a final diagnosis, doctors of affected workers initially thought that the symptoms might be due to asthma, chronic bronchitis, emphysema, pneumonia, or smoking," NIOSH reported on this page.

The agency says affected workers should be promptly referred for further medical evaluation if they have a persistent cough; persistent shortness of breath on exertion; frequent or persistent symptoms of eye, nose, throat, or skin irritation; abnormal lung function on spirometry testing; or accelerated decline in lung function. "Physicians should advise workers about any suspected or confirmed medical condition that may be caused or aggravated by work exposures, about recommendations for further evaluation and treatment, and specifically about any recommended restriction of the worker's exposure (including removal from the workplace) or use of personal protective equipment. To date, most cases have shown little or no response to medical treatment. Affected workers generally notice a gradual reduction or cessation of cough years after they are no longer exposed to flavoring vapors, but abnormalities on lung function tests and shortness of breath on exertion persist. Several with very severe disease were placed on lung transplant waiting lists. Workers exposed to flavorings may also experience eye, nose, throat, and skin irritation. In some cases, chemical eye burns have required medical treatment. While most workers with very severe flavoring-related lung disease have shown evidence of bronchiolitis oblliterans, it is possible that some workers exposed to flavoring chemicals may develop new-onset asthma or exacerbation of pre-existing asthma."

Workers and safety managers are asked to report lung problems they suspect might be related to work with flavorings to NIOSH, which can conduct health hazard evaluations in such cases, and the agency recommends that cases be reported to local and state public health departments.

References

1. https://www.cdc.gov/niosh/topics/flavorings/

2. https://www.cdc.gov/niosh/docs/2016-111/pdfs/2016-111-ExecSum.pdf

This article originally appeared in the February 2017 issue of Occupational Health & Safety.